Most of the new people in the die cutting industry began to enter the industry through acquaintances, so many are industry white, there are also some graduates from the mold, or experienced personnel related to electronics and mobile phone accessories. Relatively speaking, if it is a mechanical or mold industry graduate still has the advantage, the acceptance ability is strong, can understand some drawings and product structure.

Die cutting new, can be said to be the new blood of various positions in the die cutting industry, without the supplement of new blood, the industry will not have a way to operate reasonably, so what work can die cutting new people do? How to do, in order to avoid detours?

First, die cutting master

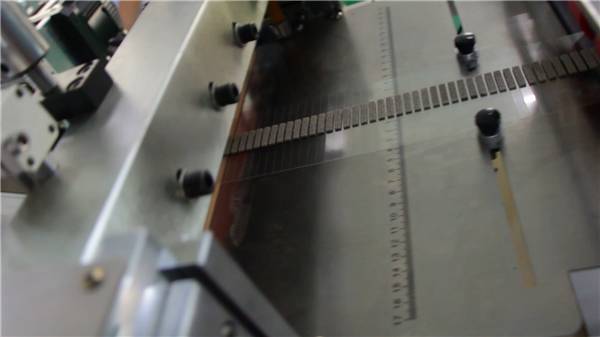

This position can be said to be a generalist, many mobile phone accessories products are made through die-cutting processing, the most basic contact die-cutting industry is to boot, the project to the product drawings, we must know how to read the drawings, familiar with the trial mold, mold adjustment, and can solve some simple problems encountered in the die-cutting operation.

Die cutting master need to master a few skills:

1, boot:

In order to become a qualified die cutting master, in addition to being very familiar with the machine operation in the factory, such as how to adjust the machine, how to accurately adjust the mold, the basic matching skills of materials, etc., we should do more to see, ask more questions, listen more, practice more, and pay more attention to the related process books or weekly classes of the die cutting industry. Perhaps at this time, someone asked the die-cutting industry is converted from printing to new electronic digital mobile phone peripheral accessories die-cutting processing, there is little information in this respect, how do we understand the industry information? There is now a "die cutting horizon" book, which is a technical tool reading book in the die cutting industry. You can learn a lot of technical process knowledge in it, in addition, the die cutting forum will also have a lot of practical things.

On the paper to get the final sense of shallow, they also want to study more, do not understand and then consult others, accumulate experience, form their own set of die cutting technology.

2. Product structure:

This part is also to understand as a boot master, when nothing is OK, take a few samples to disassemble, research, if you really do not know, find the simplest way to decompose an unused or bad old mobile phone, which product link does not understand, ask an experienced master, 3-4 months down, a little more complex die cutting product structure should also be a problem, If it is some simple die-cutting products, then the operation is even simpler.

3. Can read drawings:

In general, the factory requires the die cutting master to read the drawings, if not, in fact, simple operation, and then listen to the master, there is no problem.

Two, each processing post master

This is currently the largest number of die-cutting industry processing factory, because in recent years, the rise of mobile phones, die-cutting industry assembly line operation mode increase, the need for various positions of die-cutting machine master, because each mobile phone accessories products, electronic products are not the same, the use of the machine is not the same, so these positions of the master familiar with all kinds of machines is also very important. Like the industry used more: Chide, Vistar, Feixinda, Kunlun and other machines. These positions basically belong to die cutting technicians, technology to a certain extent can be considered to learn more and then promoted to engineers.

Three, die cutting engineer

Die-cutting engineers in the die-cutting industry is more powerful, this position is the most difficult to learn the die-cutting industry, because the die-cutting engineers need to master things are really too much, easy to learn difficult to fine, the same, the salary of this position is relatively high, even if the level is general, but also has the processing master of the middle level of wages. Of course, friends who want to enter this post do not have to worry, that is, it will take a longer time, have more experience, and at the same time use more brains to draw inferential examples.

1. Knife die

To understand the layout of the die, it is related to how to save materials, time and effort... The accuracy of the adjusting die is designed and adjusted according to the requirements of the product from the aspects of width and height.

2, processing technology

The understanding of the processing technology is the same as that of the above die cutting master, or even more in-depth, mainly to consider the design impact of the product processing technology specified by some customers, mainly: material understanding and collocation, the defects encountered in various process technologies and solutions, the problem of the cutter die, SOP operation, product waste and so on. This ability is very important, if a die cutting engineer does not consider thoroughly, then in the die cutting processing will certainly encounter various problems.

So, how to master all the die cutting processing technology? In fact, it is not difficult to figure out, because the die cutting project is not the same as the standard for processing and boot master, boot master is the general die cutting master whose standard is to be able to do things, to be accurate, to be good, to be fast. The understanding of the technical process of die-cutting engineering is actually as long as you know the principle of the product process, the nature of the range, the way, the accuracy, the time, the cost, the effect, etc., and you do not use hands-on operation, of course, the premise is that you will hands-on operation.

Just like people who can drive may not necessarily repair cars, new people who aim at die cutting engineering, when learning the process, they do not have to operate all the machines, but they must understand. Look more, ask more, think more, find out why the design of drawings? How can waste be discharged more easily? How to improve the yield? If you hold such a purpose to learn, to observe, one day can easily solve the die-cutting technology of the difficult problems, the engineer's name is stable.

3, the collocation of materials

Do die cutting processing familiar with the material is inevitable, and a variety of materials, each and subdivided different characteristics and usage, preservation methods, stripping force, etc. So understand the material collocation is very key, related to the problem of waste discharge, improve product yield and human, machine, material, material, method and other links. Ultimately to reduce costs to create profits.

So how do you do that? In front of the structure of the product, there is time to see what materials match the structure of each product, some products have only three layers, like the dust filter has reached seven layers, each material is different, and it is also quite exquisite.

4. Software ability

Some new people who have just entered the field may have been in contact with the school, some may be ignorant, do not understand it does not matter, the direction is set, the foundation is secondary, the important thing is perseverance.

Learning software is also a step, the most simple, the most basic CAD, this thing is a must, CAD this classic drawing software is not outdated. In the study of this software, I want to emphasize the use of shortcut keys. The basic principle of using shortcut keys is to improve the command input speed. The passing standard is to type all the commonly used commands with one hand without looking at the keyboard. If you can reach this standard, basically the speed will not be bad.

If a friend is to do die cutting engineering, that is to find a friend to consult more, behind closed doors is far less important than having a good coach, in this industry, personally experienced die cutting master is still different, less to take a lot of detours. It's amazing to learn a third of it.

Summary: For the die cutting new people how to mix the die cutting industry here, there is no guarantee that you can learn what, because the master leads the door, practice depends on the individual, this still depends on your own. This article is mainly to let the novices no longer blind, have a clear goal, have a clear direction and steps, the next is to adhere to, can bear hardships and stand hard work, how far can go by their own nature.

※ Notice: Some content excerpts of the network, if the copyright of the work is involved, please contact us in time, we will delete the content to ensure your rights and interests.